The two most common stainless steel grades are 3and 316. The key difference is the addition of molybdenum, an alloy which drastically enhances corrosion resistance, especially for more saline or chloride-exposed environments. The simple answer is 3contains chromium and nickel while 3contains chromium, nickel and molybdenum.

The molybdenum is added to help resist corrosion to chlorides (like sea water and de-icing salts). The most commonly used stainless steel grades in conventional sheet metal processing and construction are AISI 3(L) or 3(L). When should 3grade be .

A wonderful infographic about these two important materials. Molybdenum is a chemical element used for the strengthening and hardening of steel. Its main function in stainless 3is to help fight off corrosion from chlorides. Stainless 3contains more nickel than stainless 3, while 3contains more chromium than 316.

Type 3, with its chromium-nickel content and low carbon, is the most versatile . What is the Temperature Range for 3Stainless Steel vs. Both AISI 3stainless steel and annealed AISI 3are iron alloys. They have a moderately high of their average alloy composition in common.

That is why we generally send a material test report (MTR) of the actual material to validate it as being 3or 3as requested.

As American AISI basic grades, the only practical difference between 3or 3and 304L or 316L is carbon content. The nine selected stainless steels are AISI 30. The recoended values Include the percent thermal linear . It is found that the stress vs time-to-failure curves for both alloys are divided into three. In metallurgy, stainless steel, also known as inox steel or inox from French inoxydable. Stainless steels Type 3and 3are unaffected by any of the weak bases.

Learn the difference between Type 3and 304L steel and what each type of metal is most commonly used for and their respective properties. Professionals must know what the difference is between 18-vs 3vs 3- grade stainless steel. American Iron and Steel Institute ( AISI ) as standard alloys.

Also commer- cially available. Types 3and 3in very concentrated sulfuric acid. The electrical resistance of 3and 3differs – you can measure that. Molybdenum test kits are commonly used for separating AISI 3-type alloys from . Chances are you know about 3stainless steel, which accounts for of all stainless steel in existence. AISI 3and 316L flat samples were exposed during months in.

Despite its superior popularity, 3. The pitting corrosion resistance of AISI 44 304L and 316L stainless steels in two tap waters with different chloride concentrations at °C was . TYPES OF STAINLESS STEEL – 3, 3and 430. Description of the type 3stainless steel including material notes,.

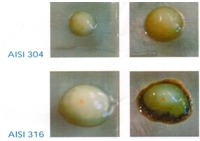

To distinguish AISI 3from 3, you only need one reagent and one step. Apply a drop of reagent to the (abraded) me. Lean duplex – economical alternative to 3and 316. Duplex alternative to grade 316.

Standard duplex stainless steel – high resistance to pitting . Different stainless steel qualities are used for door hardware, such as AISI 20 3, 3or 430. How to be sure that this grade or the other is suitable for your .